Description

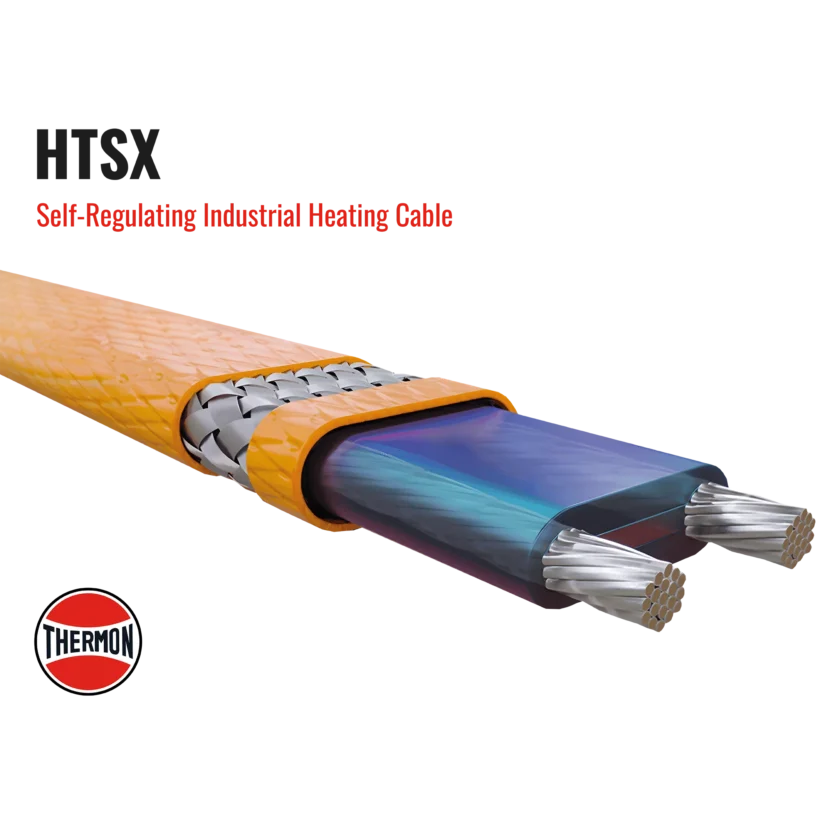

The Thermon HTSX Self-Regulating Industrial Heat Tracing Cable stands as a pinnacle of advanced technology, designed explicitly for process temperature maintenance or freeze protection applications demanding high-temperature exposure capabilities. Engineered to withstand the temperature exposures associated with steam purging, the HTSX cable is constructed using Thermon’s unique and proven monolithic co-extrusion process, establishing itself as a market-leading self-regulating heat tracing technology.

The distinguishing feature of the HTSX trace heaters lies in their self-regulating capability. The heat output dynamically responds to the surrounding temperature, compensating automatically for variations in ambient temperature or heat loss through thermal insulation along the entire length of a heat-traced pipe. This intelligent and adaptive functionality ensures energy efficiency and precise temperature control, making the HTSX cable a reliable choice for critical processes.

Approved for use in both ordinary (non-classified) areas and hazardous (classified) areas, the HTSX Self-Regulating Industrial Heat Tracing Cable meets stringent safety standards, making it suitable for a wide range of industrial applications. Its robust construction, coupled with the ability to endure high-temperature exposures, positions the HTSX cable as a dependable and market-leading solution for demanding heat tracing requirements.

- Nickel-plated copper bus wires 1.3 mm2 (16 AWG)

- Semiconductive heating matrix and fluoropolymer dielectric insulation

- Nickel-plated copper braid

- Fluoropolymer over jacket provides additional protection to core, insulation, and braid where exposure to chemicals or corrosives is expected.

- Available power densities

10, 20, 30, 33 3, 39, 49, 66 W/m @ 10°C

(3, 6, 9, 10 3, 12, 15, 20 W/ft @ 50°F) - Supply voltages

110-120, 208-277, or 380-480 Vac - Max. maintenance temperatur

(110-277 Vac) 150°C (302°F)

(380-480 Vac) 121°C (250°F) - Max. exposure temperature

Intermittent power-on or off

(110-277 Vac) 250°C (482°F)

(380-480 Vac) 204°C (400°F)

Continuous power-off

204°C (400°F) - Minimum installation temperature

-60°C (-76°F) - Minimum bend radius

@ 5°F (-15°C) 10 mm (0.38”)

@ -76°F (-60°C) 32 mm (1.25”) - T-rating

1 3-1, 3-2, 6-1, 6-2, 9-1, 9-2, 10-4, 12-1, 12-2, 15-2, 15-4 T3 200°C (392°F)

15-1 and 20-1 T2D 215°C (419°F)

20-2, 20-4 T2C 230°C (446°F)

Based on stabilized design T3 to T6

Reviews

There are no reviews yet.